Benefits of ASMR or ASMC Modules

BPM provide a variety of different socket modules and daughter cards, from manual opening to automated sprung sockets.

Typically over the life of these modules, contacts can wear out which in turn produces continuity or programming issues because the device is not making sufficient electrical contact with the socket pins.

In most cases, these sockets are soldered to the daughter card or socket module and due to fine pitch and the leads, specialist desoldering tools are required to replace the sockets.

BPM considered this scenario and provide a more cost effective "R" for receptacle and "C" for compression, socket.

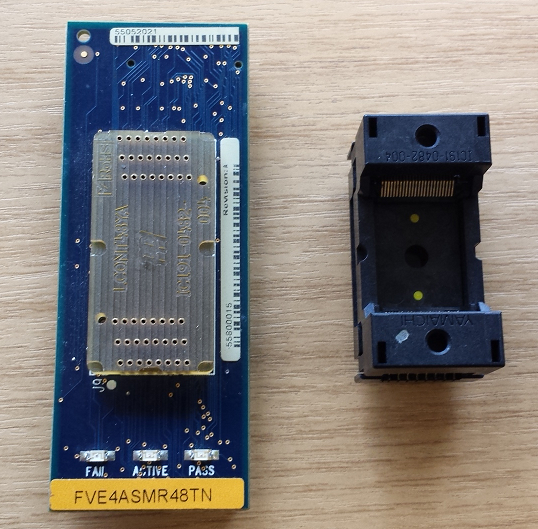

Receptacle

These types of sockets allow for the worn socket to be simply lifted off of the module or daughter card so that they can be exchanged for a new socket, as seen in the following picture.

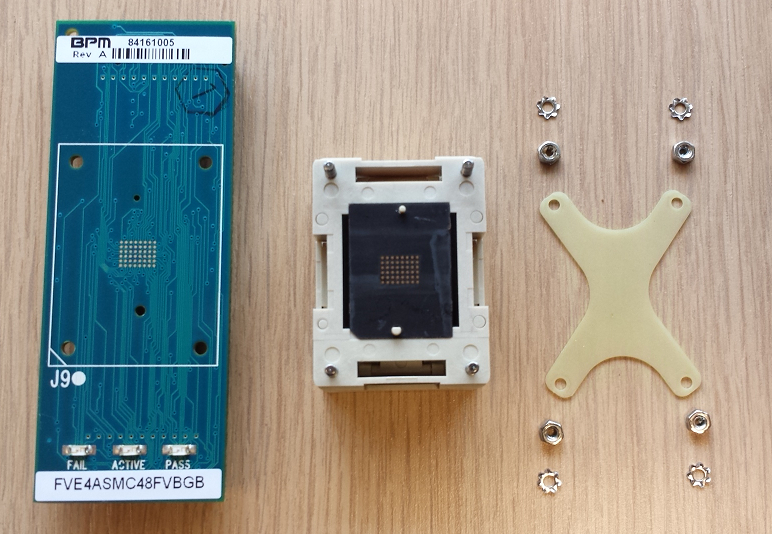

Compression

This type offers the same benefits as Receptacle types, but requires a little more work as they are typically fixed to the PCB using nuts to ensure a secure and tight contact to the contact pads, as seen in the following picture.

Both types provide a much lower support cost over fixed type sockets as the replacement sockets are only a fraction of the cost of a complete module or daughter card.

It is recommended that the insert counts are reset when a socket is changed, to allow tracking of the number of inserts each module or daughter card has processed.

More information of socket part numbering can be found here: https://www.adaptsys.com/support-services/bpm-support/kb/article/bpm-part-number-description-summary

Alternatively, speak with your local sales/service engineer to check availability of receptacle or compression modules or for replacement sockets.

Related Articles

Automated Socket Modules and Pressure Plates

For a full list of Automated Socket Modules and the Pressure Plates required to be used on automated handlers, then please view the list here.Which Socket Modules can I use

When there is a requirement to program a device, you will need to know which socket module is required to interface the device to the programmer. This can be found out within BPWin using the following steps. 1. Run BPWin (You do not need to have a ...BP- 3000 Series Autohandler Maintenance

Weekly – 10 minutes Dust off programmer sites and socket modules with clean, dry compressed air. Inspect Z-rod bellows for proper movement (compression and extension). Check nozzle runout. Replace bellows if run-out is greater than 8 mils. Remove ...BP- 4000 Series Autohandler Maintenance

Weekly – 10 minutes Inspect nozzle O-rings and replace, as necessary. Inspect Z-rod bellows for proper movement (compression and extension). Check nozzle runout. Check air and vacuum gauges. Remove debris and devices from work area. Dust off ...Read Socket Insert Count

How can I use BPWin API to read back the insert count of the installed socket modules? BPWin API does provide insertion counts via "The SystemInformation XML document", which can be retrieved using the "GetSystemInfo" method as well as the ...