How to Clean Sockets

What are the preventative maintenance and cleaning methods recommended for various socket types?

What are the preventative maintenance and cleaning methods recommended for various socket types?

Summary

Over the lifetime of a socket, various factors can cause the socket performance to degrade. The purpose of this document is to detail preventative maintenance and cleaning methods recommended for various socket types. BPM Tech Support should be contacted if within the normal life cycle of a socket, following these procedures does not improve socket yield or if socket yields deteriorate rapidly early in the life of a socket.

Details

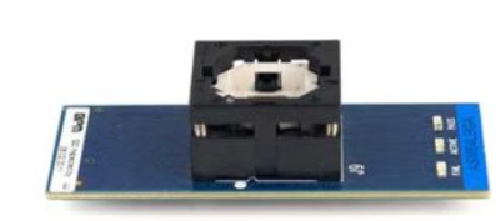

| Socket Categorization There are 3 basic types of sockets from a cleaning perspective.

|

Prevention Techniques

|

Causes for Socket Degradation and sequence of steps for resolution

There are 3 primary causes of degraded socket performance.

|

Procedures applicable to specific socket categories

|

Socket Cleaning Procedures

Using a clean dry air source blow compressed air into the socket nest. If possible vary the angle and position of the nozzle tip so that any dust/debris which is inside the socket nest is pushed on from different angles and therefore has the best opportunity to be pushed out of the frame.

Soft Bristle Brush Cleaning is generally used for helping to remove any dust and debris from inside the socket nest. To do this, gently brush the socket nest from multiple angles to help dislodge any dust or debris.

This can be used to remove any dust or dirt that has accumulated on the pad of an elastomer socket. To do this place the magic tape onto the pad and then simply remove it. The idea is that any dust or dirt will remain attached to the tape which can then be discarded. The tape should not be allowed to sit on the surface and should not be pressed into place with a lot of force. Please note, applying too much pressure onto the Elastomer pad can cause damage. This method should be used only after a concern has been identified.

Cleaning devices can be purchased that are made based on the size and shape of the device being programmed by the socket in question.

Cleaning devices are rated to clean sockets for 250 touchdowns after which they should be discarded and a different cleaning device used. Cleaning devices are best used as tools for preventative maintenance.

This method of cleaning has been available for a long time and can be very effective for cases where the socket can be removed from the PCB. The disadvantages are that in general, a whole socket will need to be subjected to the cleaning process so the choice of cleaning solution is critical. Never immerse the socket in an untried solution. If a newly available solution is applied to the socket this should be done first using the Chemical Tip Cleaning method so that any damage to socket pins or housing can be observed. The standard method for cleaning a socket using an ultrasonic bath is to:

Finally, there are companies that specialize in cleaning and revitalizing previously used sockets to maximize the socket life. The disadvantage of this is that sockets will need to be shipped off-site and there is an additional time delay, but the result in time-saving and cost-effectiveness can easily justify this method. One vendor that BPM has used with good success in the past is Nu Signal. | |||||||||||||||||||||||||||||

Related Articles

Preventative maintenance and cleaning methods for various socket types

Summary Over the lifetime of a socket various factors can cause the socket performance to degrade. The purpose of this document is to detail preventative maintenance and cleaning methods recommended for various socket types. Adaptsys Support should ...Do you have any idea of the life cycle for a socket module?

If properly cared for the socket module base, the part that connects to the programmer, should last for 10's of thousands of cycles, regardless of the package. It is important the care is taken during installation and removal of the module from the ...BP- 3000 Series Autohandler Maintenance

Weekly – 10 minutes Dust off programmer sites and socket modules with clean, dry compressed air. Inspect Z-rod bellows for proper movement (compression and extension). Check nozzle runout. Replace bellows if run-out is greater than 8 mils. Remove ...X800 Valid Site Configurations

On 8th Generation programming sites, upto 4 sockets cards can be place per programming site. With automated handlers, we employ stepper motors to pull down pressure plates to open and close the sockets and each device algo had code to establish to ...Socket Module Troubleshooting

Summary Sockets and daughter cards are considered consummables and are not warrantied. BPM Microsystems will warranty the motherboard of the socket module for one year from purchase against defects in workmanship and component failure. This does not ...