Nozzle Runout

This test should be used to ensure that the Pick-and-Place nozzle is installed properly and that the CyberOptics Laser Align Camera will accurately measure a device during placement. A large runout can cause the CyberOptics Laser Align Camera to incorrectly measure a device during placement and therefore misplace the device. The test is automatically run at initialization and at the beginning of the job.

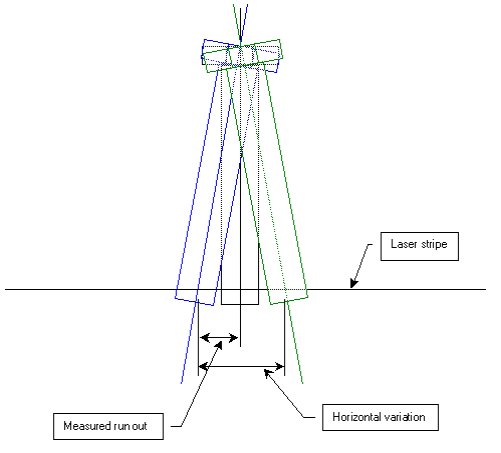

The horizontal variation of the Pick-and-Place nozzle is measured from the perspective of the CyberOptics Laser Align Camera.

The CyberOptics Laser Align Camera captures images of the Pick-and-Place nozzle while the Pick-and-Place nozzle is rotated 360 degrees. This measurement is reported in mils (thousands of an inch; 1 mil = 25.4 µm).

After the horizontal variation is measured, the Pick-and-Place nozzle is adjusted for best alignment with the CyberOptics Laser Align Camera by rotating the Pick-and-Place nozzle so that it is positioned in the center of the horizontal variation.

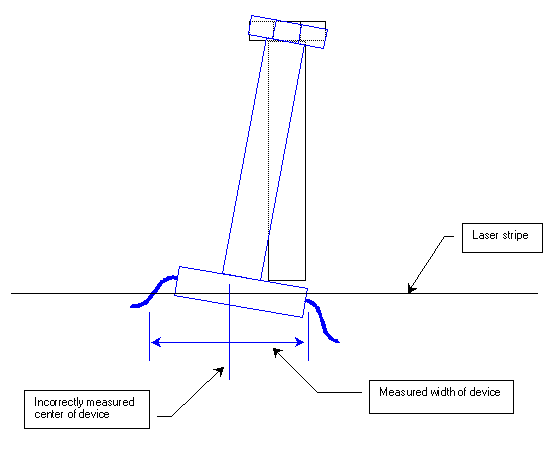

The Pick-and-Place nozzle runout affects the performance of a device pick, device measurement, and device placement operations. For example, a large Pick-and-Place nozzle runout can cause the CyberOptics Laser Align Camera to incorrectly measure a device as illustrated below.

Because the measured center of the device is incorrect, the accuracy of device placement will be compromised. This large Pick-and-Place nozzle runout can also affect the pick performance of a device by creating a vacuum leak between the Pick-and-Place nozzle and the contact surface of the device. This vacuum leak will produce mis-picks or will reduce the DPH because a vacuum seal between the Pick-and-Place nozzle and the contact surface of the device will be delayed until the Pick-and-Place nozzle is retracted. This pick performance problem becomes more apparent when using very small packages due to the small contact surface of the package. Therefore it is recommended that the Pick-and-Place nozzle have a measured runout close to zero for optimal device pick, device measurement, and device placement performance during a job session or a station teach session.

Before a job session or a station teach session, BPWin will verify that the measured runout is within a recommended maximum runout for the selected package. If the measured runout exceeds the recommended maximum runout for the selected package, you will be presented with the option to continue using the Pick-and-Place nozzle with the large measured runout or cancel the current operation to correct the problem. Note that the recommended maximum runout is defined as a runout that can be tolerated by the Pick-and-Place subsystem but will result in suboptimal performance.

BPWin will also verify that the nozzle is of an appropriate size for the selected package.

Related Articles

Camera to Nozzle Coplanar Alignment

Summary Step-by-step guide on how to check and adjust the Camera to Nozzle Coplanar Alignment on 3x00 and 4x00 APS Details For the BPM Microsystems handlers to correctly and accurately measure and align devices for accurate placement, the nozzle ...BPM APS Nozzle Chart

Devices stick to Nozzle

Symptoms When the nozzle goes down to place a device into a socket or other location, the device remains on the nozzle. As the nozzle returns to the Z home position, the device will then fall out of the nozzle. This issue can occur when changing jobs ...Poor Nozzle Vacuum

If you are having issues teaching a device or location and are seeing vacuum related errors then this guide could help. In BPWin, there are some additional I/O and Sensor Diagnostics functions which should be used in this situation. BPM autohandlers ...BPM Automated Pick and Place Issues

Indicators Pick errors, place errors or vision centering problems occur frequently during a job session. Troubleshoot Ensure that the stations and the package are taught correctly. This is the cause of the majority of Pick-and-Place problems. Run the ...