Vacuum pressure too low on 4000 Series APS

Summary

Weak vacuum at the nozzle prevents location to teach.

Details

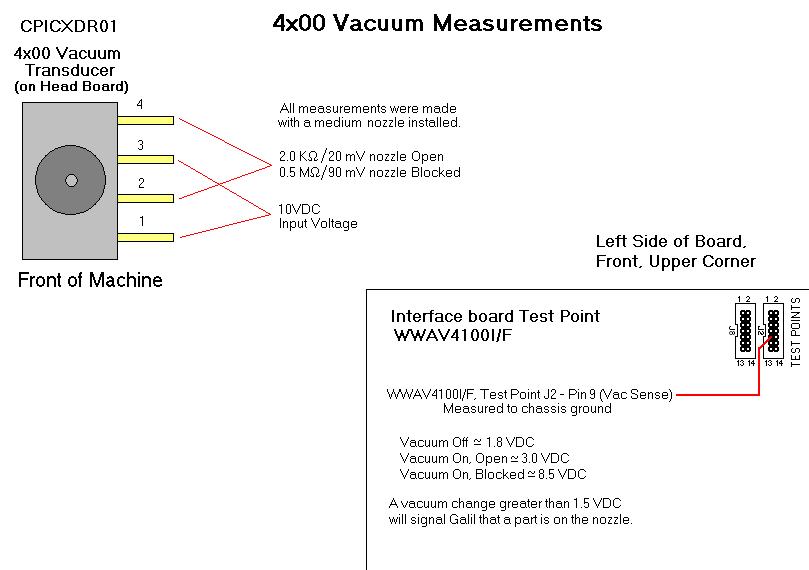

The vacuum values on the I/O and Sensors Diagnostic dialog are a function of the vacuum transducer. If the vacuum is weak, the transducer will not change much, and these values will change little as well.

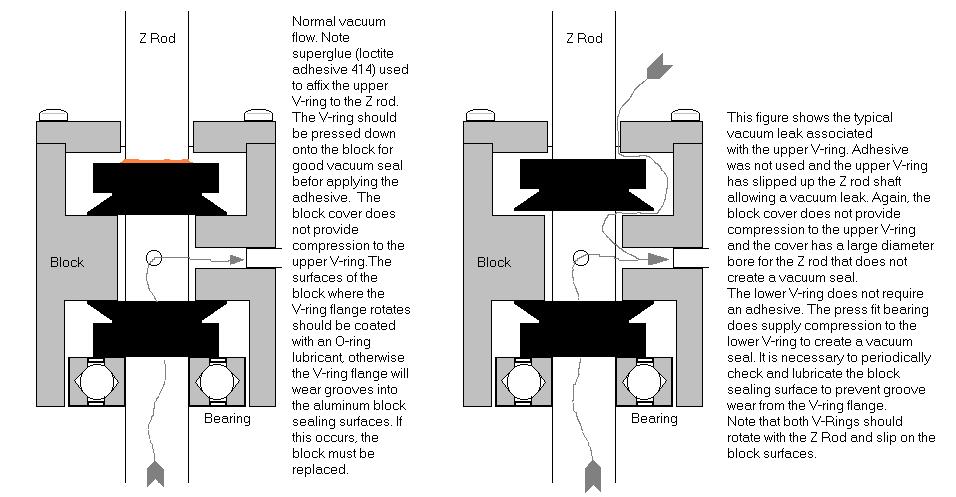

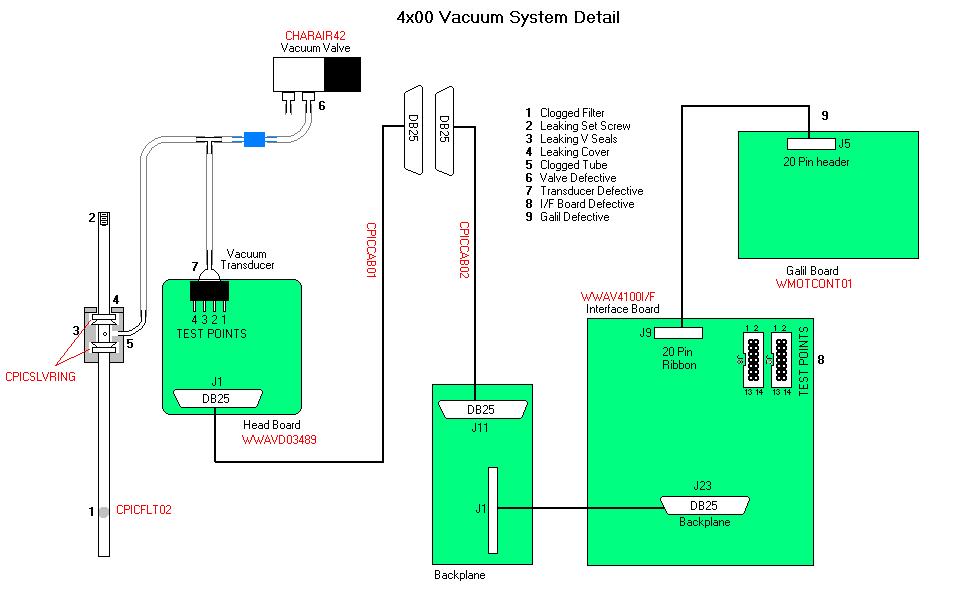

What is the reading on the vacuum gauge on the pneumatics panel? Less than 20 in/Hg is sign a problem. It could be a leak in the vacuum lines, a defective vacuum generator or vacuum valve. If the vacuum generator is good, go up to the head and pull the vacuum hose off the curved metal tube on the Z rod, and check the vacuum at the hose. If the vacuum is strong there, but weak at the nozzle, then the leak is inside the Z rod, probably the V-rings. If the vacuum is weak, the problem could be the in-line vacuum filter or the vacuum valve. Finally, there could be a split or cracked hose in the e-chain.

Related Articles

Vacuum pressure too low on 3000 Series APS

Summary Weak vacuum at the nozzle prevents location teach. Details If you suspect weak vacuum at the pick and place(PNP) nozzle, follow this procedure. Check the input air regulator located inside the pneumatics box. The rightmost regulator should be ...BP- 3000 Series Autohandler Maintenance

Weekly – 10 minutes Dust off programmer sites and socket modules with clean, dry compressed air. Inspect Z-rod bellows for proper movement (compression and extension). Check nozzle runout. Replace bellows if run-out is greater than 8 mils. Remove ...Poor Nozzle Vacuum

If you are having issues teaching a device or location and are seeing vacuum related errors then this guide could help. In BPWin, there are some additional I/O and Sensor Diagnostics functions which should be used in this situation. BPM autohandlers ...BP- 4000 Series Autohandler Maintenance

Weekly – 10 minutes Inspect nozzle O-rings and replace, as necessary. Inspect Z-rod bellows for proper movement (compression and extension). Check nozzle runout. Check air and vacuum gauges. Remove debris and devices from work area. Dust off ...Very Small Package (VSP) Handling and Teach Considerations

Summary Checklist for successfully teaching and handling VSP Devices. Details Note that the BPM Microsystems specification sheet lists the SOT23 at 2.95 mm by 1.63 mm as the smallest device supported. Devices smaller than this will not be supported, ...